Axial Blast IQF Tunnel Freezer

Axial blast IQF tunnel freezer is a common type of food freezing machine, which equips axial fans to circulate air inside. It is widely used in the freezing and processing of seafood, poultry, meat, snacks and other foodstuffs. Especially for strip, cubic or grain food. This IQF freezing is consisted of double stainless steel covering insulation freezing room, aluminum fins and coils evaporator, stainless steel belt and frame. Axial blast IQF Tunnel freezer is easy to assemble, operate and maintain.

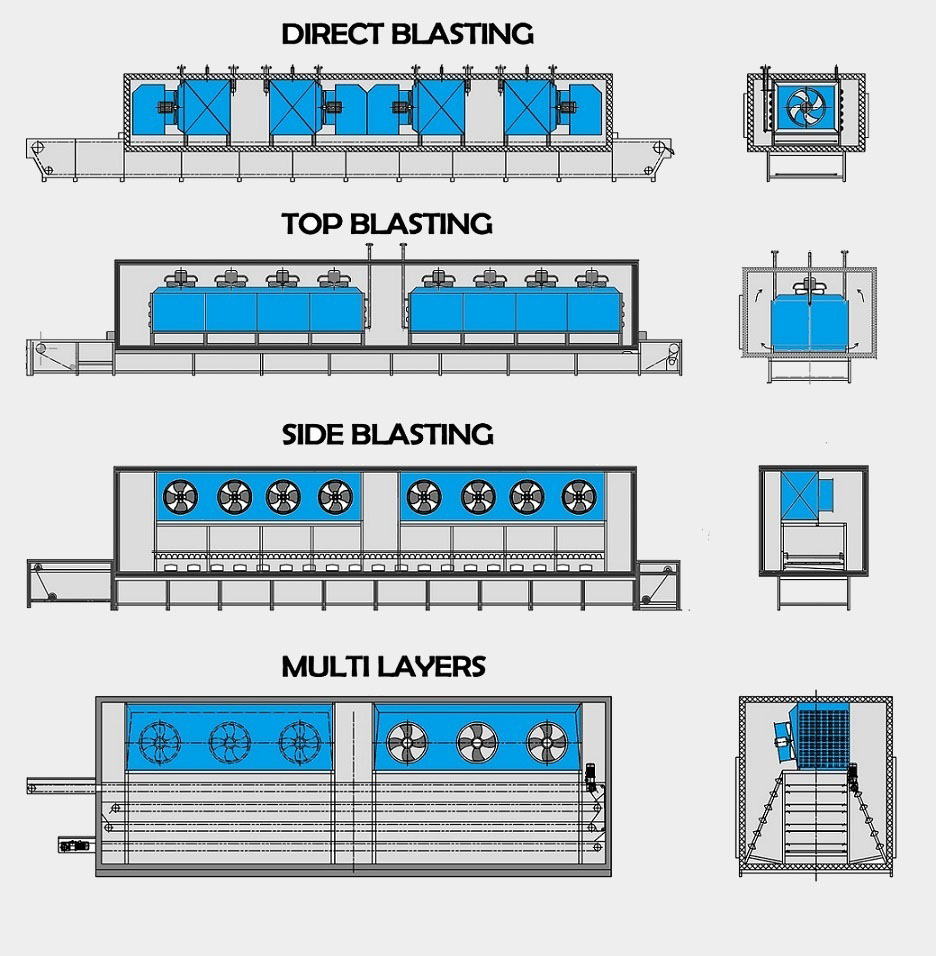

The tunnel freezer has 3 types of fan arrangement: direct(SSD models), side(SCD models) and top(SDD models). Direct blast is avaliable to be wide belt model (SSDK), and side blast can be multi-layer model (SCDM). Different types have different evaporator structures and airflow configurations, which are suitable for different frozen products. SSDK and SCDM are the two models for large freezing capacity, the max capacity can reach to 2 tons/h.

Application

Shrimp, meat balls, ham, pasta, grains, langoustine, clams, hairtail, sliced fish, dumpling, pig tongue, chicken, etc.

Features

• Multi-layer and multi directional blast freezing for selection

• Rational arrangement of large capacity axial fan improve refrigeration efficiently

• Blasting and frame of tunnel freezer are made of SUS 304,belt speed is variable, freezing can be controlled accurately

• Fewer cold escape from 120mm polyurethane insulated panel with 0.4 mm stainless steel covering in two sides

• Evaporator is made of superior coils and fins, works more than 10 hours without defrosting

• 4 temperature measuring points in the different positions of freezer, the running status of the IQF machine is displayed in electrical control panel.

Performance Parameters

Food feeding temperature: +15℃

Food out-feeding temperature:-18℃

Freezing capacity (based on shrimp): 300-2000kg/h

Freezing time:15-30 minutes

Refrigerant: R717,R22,R404a,R507c