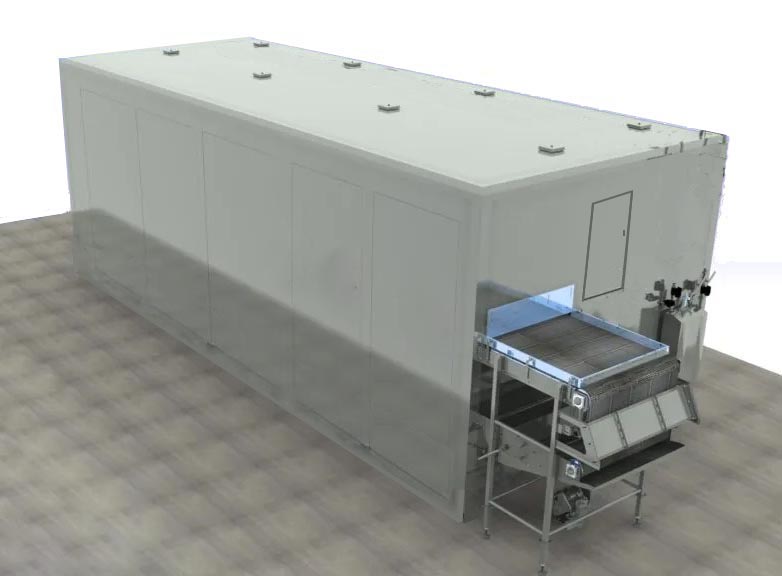

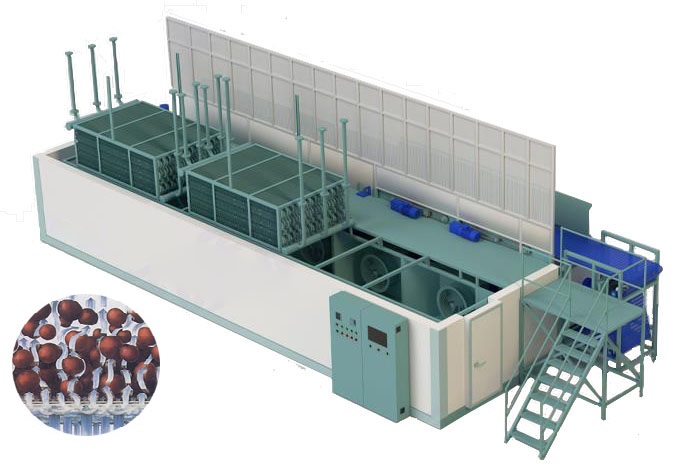

Fluidized bed IQF tunnel freezer is the freezing equipment designed for vegetables and fruits IQF freezing purpose specially. For the particular structure, raw materials of vegetables or fruits are required to be frozen in a very short time.

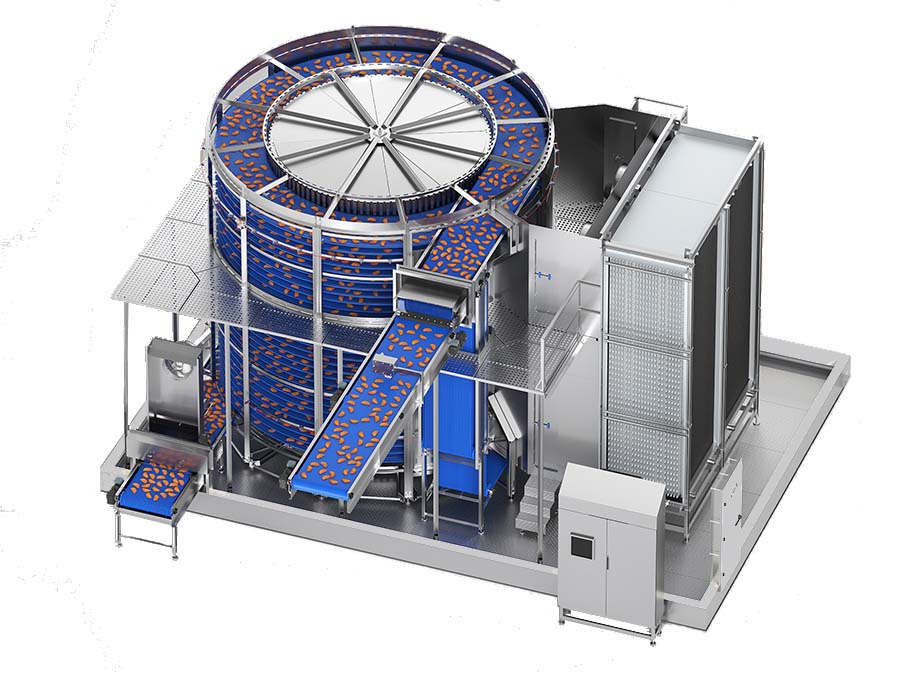

Long time freezing will lead to form block ice in cells. These block ice will damage cells and influence the quality of IQF fruits or vegetables. Instant freezing is an effective way to avoid it. Different with other freezing machines, the air blast from bottom to top, all the surface will contact with cold air evenly, articles are frozen in a short time, generally the freezing duration is 10-15 minutes. Fluidization makes freezing more deeply, quickly and thoroughly.

Our fluidized IQF tunnel freezer for vegetable and fruit correspond to standard of food hygiene. Energy saving and high efficiency. The largest capacity of the freezing machine can reach to 5000kg/h. It is also available to design based on customized requirements.

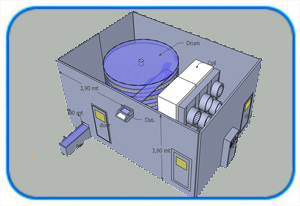

Runing Principle

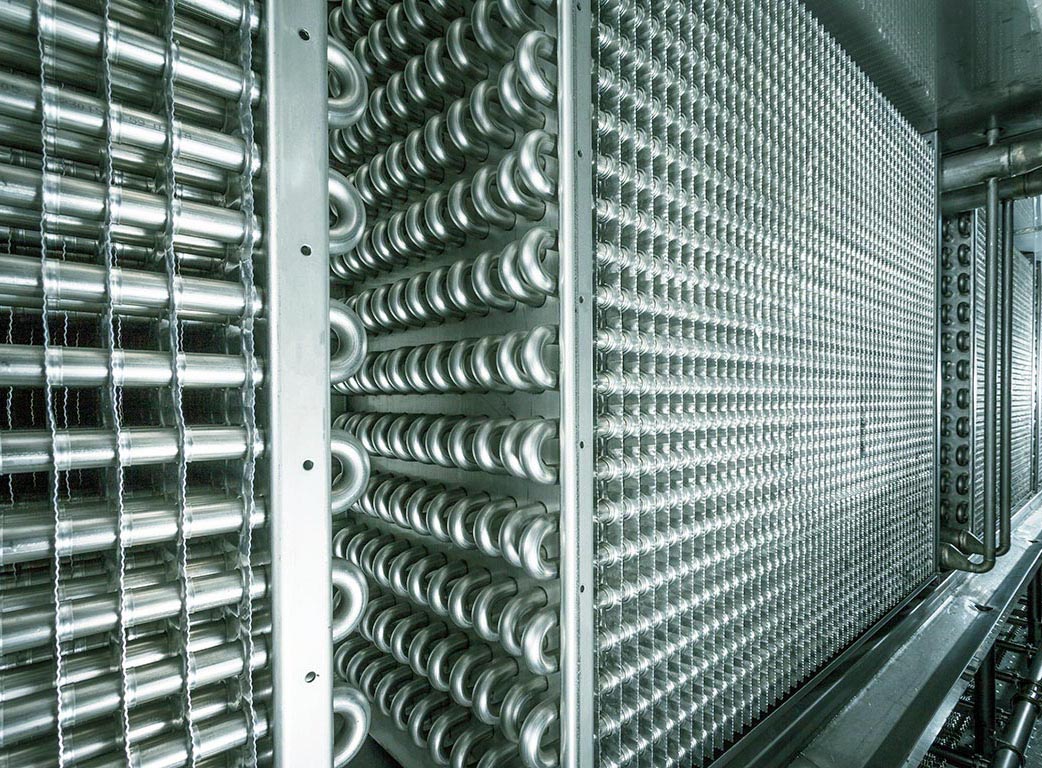

• Low temperature - Freon system supply cold energy, the evaporative temperature can be -45℃ or lower. Cryogenic environment is kept in insulation cabinet.

• Two phases freeze - Initial phase generates small ice rapidly and freeze articles surface, the duration is about 5 minutes. Final phase hardens the small ice, The core temperature reaches to -18 degrees Celsius. This duration is about 5-10 minutes.

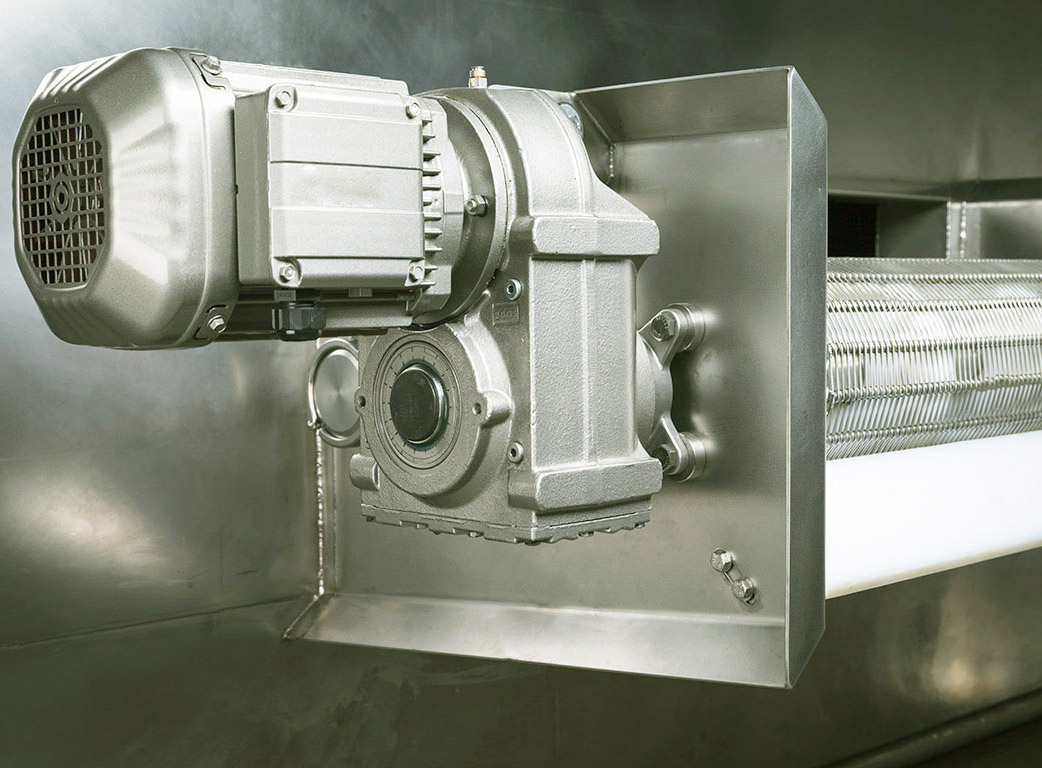

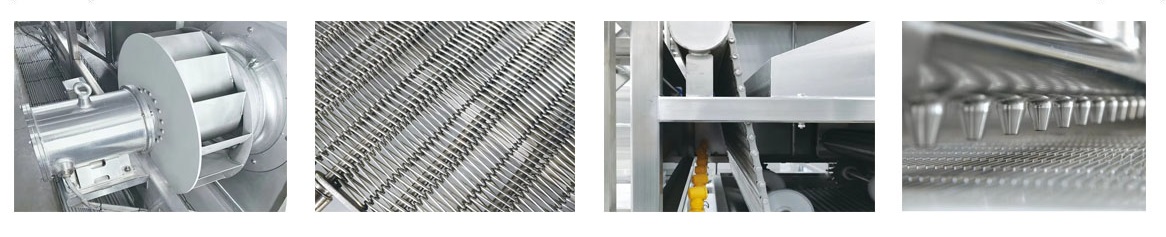

• Blast freezing - Powerful fans in the bottom of the freezer. Those fans supply enough air volume to form fluidized state.

• Vibratory conveying system rotate and tumble to prevent articles from sticking with each other.

Fluidization IQF

Ultra-cold air is blown out from the bottom of the conveyor belt, food particles are suspended in the fluidized bed state, and with the belt chaining vibration device, instant freezing can be achieved without sticking to each other. As the frozen food and the cold air are in full contact in the fluidized state, a large number of tiny ice crystals will be formed inside the frozen food rapidly. The tiny ice crystals will not damage the internal structure of the cells, and maintain the quality of the frozen products to the maximum extent. It is the best choice for IQF freezing seasonal vegetables and fruits.

Performance Parameters

Product inlet temperature: +15℃

Product outlet temperature:-18℃

Freezing capacity(based on green bean):500-5000kg/h

Refrigeration consumption: 80-140kw/ton

Freezing time:10-20 minutes

Feeding density: 3 Kg/m²

Refrigerant: Ammonia(R717),Freon(R22,R404a,R507c)

Temperature of air circulation in insulated cabinet:-38℃

Voltage: 380V 50Hz 3 Phase or Customized

Defrosting: Electric heating/water/hot gas

Frozen Products

IQF Vegetables: green pea, sweet corn, baby corn, carrot, okra, bean, mixed vegetable, broccoli, cauliflower,peppers,spinach etc.

IQF Fruits: papaya, mango, pineapple, guava, pomegranate, strawberries, coconut, etc.

PDF Catalogue