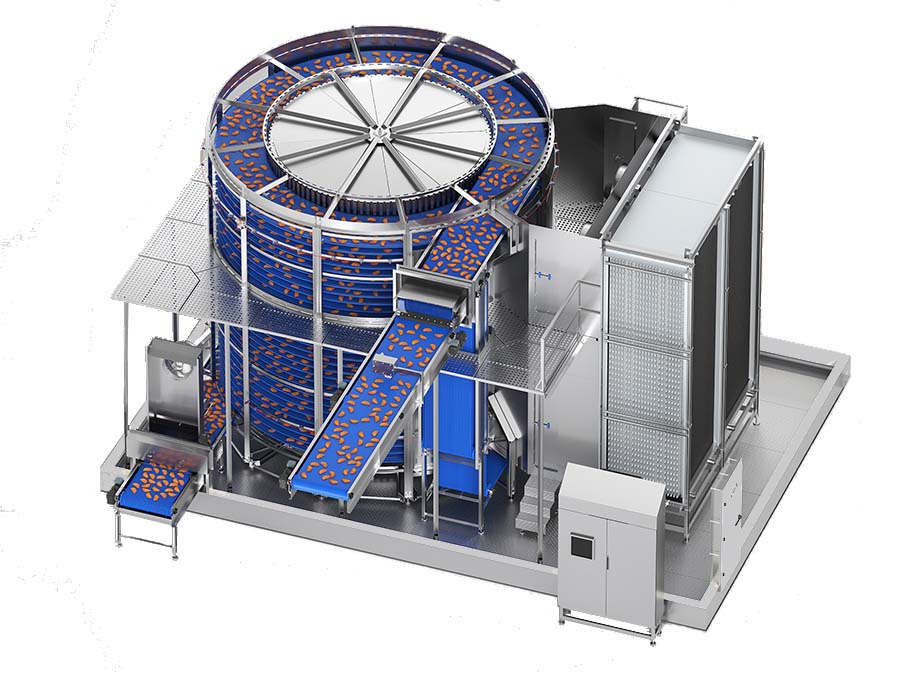

Comparing with other type IQF food freezers, spiral freezer system has its own advantages. There is a long mesh-belt in the body of the freezing system. The frozen foods stay in the cryogenic surrounding for long time. It has enough time to freeze the foods more deeply. Thanks to the long time freezing, the spiral freezer can work with small capacity compressor, it will save more investment in the refrigeration system. In the same floor space, spiral quick freezer has larger freezing capacity.

The standard models of spiral freezer system manufactured By Chenguan include single and double spiral drum. The capacity is from 500-2000 kg/h. We also provide the solutions to customized demand. We can design the freezing capacity, equipment size, belt length, inlet and outlet directions according to customers' indication.

Features

• Compact structure, saving space

• Good quality and thick body to insulate

• Stainless Steel belt, long duration to use

• Touch digital screen, easy to operate

• Optimized refrigeration design

Product Parameters

Product inlet temp: +15℃

Product outlet temp: -18℃

Feeding density: 5.5 Kg/m²

Freezing capacity: 500-4000kg/h

Refrigeration consumption:50-100kw/ton

Freezing time: 60-120 minutes

No. of Drums: 1 or 2

No. of layers: 8-16 for single drum

Layer Pitch: 120-250 mm.

Inside temperature: -36±2℃

Refrigerant: R717,R22,R404a,R507c

Height of the in and outlet: 770mm

Defrosting: Water,electric,hot gas

Voltage: 380V or customized

Available Foods

Bakery, cheese, dairy, poultry and seafood, chicken, meat, langoustine, clams, pork, shrimp and etc.

Main Parts

Belt SUS304 food grade steel wire mesh belt for spiral freezer, high strength, long service life up to 8-10 years. Highly ventilated, easy to clean, applicable width: 400-1200 mm. Optional edge guards are available to prevent products from falling. Plastic steel mesh belt is also available upon request.

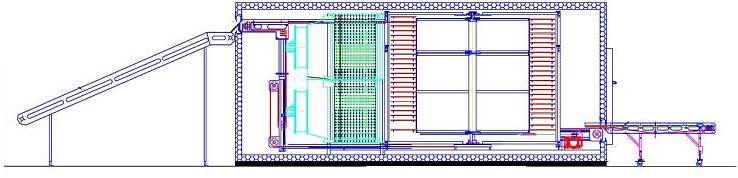

Drum The frame of the drum is made of high-strength stainless steel square tubes. Covered with SUS sheet. There are two ways to drive the drum, mount the drive motor on the top of the drum and drive its shaft directly. Or the motor is mounted at the bottom, and the drum is driven indirectly by a chain. Generally the drum is a complete part. However, the drum diameter of the large capacity spiral freezer will exceed the width of the container, and then we will design the drum to be detachable for easy transport.

Evaporator The tubes are made of copper or aluminium tubes and the fins are aluminium fins. All tubes are hydraulically expanded, which results in a more uniform expansion and a tighter fit between the tube and fins, thus improving heat exchange efficiency. Variable fin spacing is used to retard fin surface frosting. Longer frost intervals. Easy to clean and access.

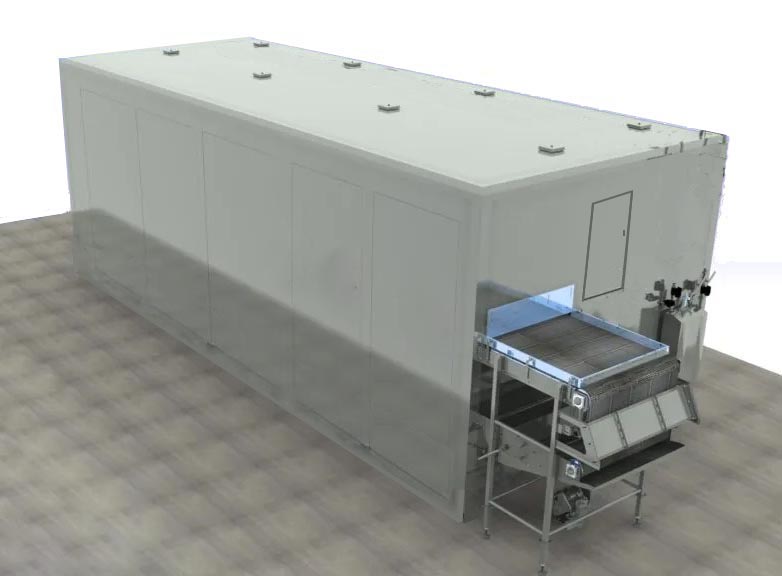

Insulated Cabinet is assembled from polyurethane panels with a thickness of 120mm. Both sides of the plate are covered with 0.5mm stainless steel plate, which meets the food-grade hygiene requirements. There are reinforcement points in the bottom panels to support the drums and evaporator and prevent the bottom panels from deformation. The floor is made of 3mm stainless steel plate with full welding.

PDF Catalogue